Challenges:

|

Solution:

|

Results:

|

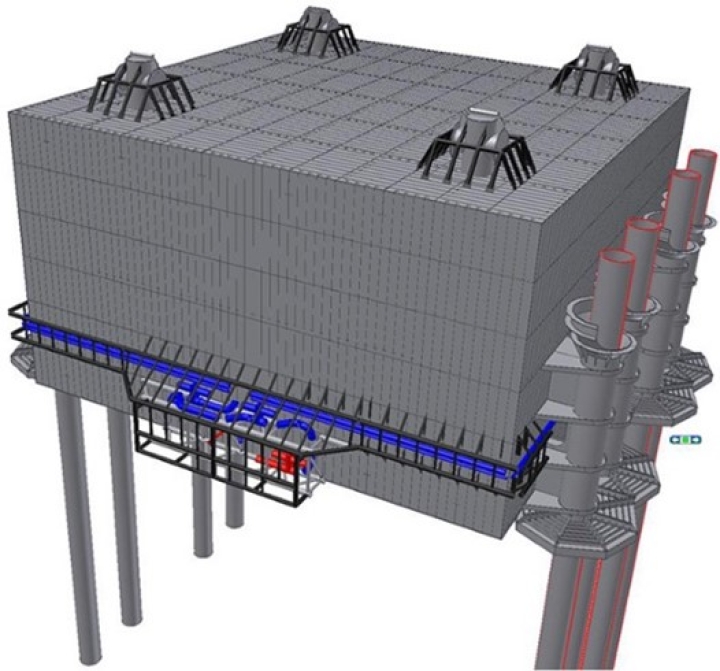

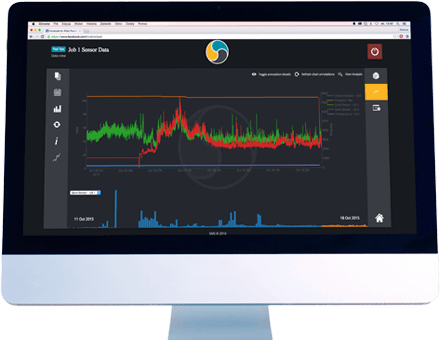

• A number of software versions developed to fulfil data acquisition & management scope • All equipment tested and fully integrated during SOST pre-deployment at wet docks • Datasets from the tank internal sensing array handed off to the topsides acquisition system via the subsea umbilical tether unit (SUTU). • Topsides acquisition module fully integrated with client distributed control system (DCS) • System fully commissioned offshore with Operator handover |

Value to Client:

|

To download this case study please click here .

| Contact us at This email address is being protected from spambots. You need JavaScript enabled to view it. or click here for more details on our services. |