Challenges:

|

Solution:

|

Results:

|

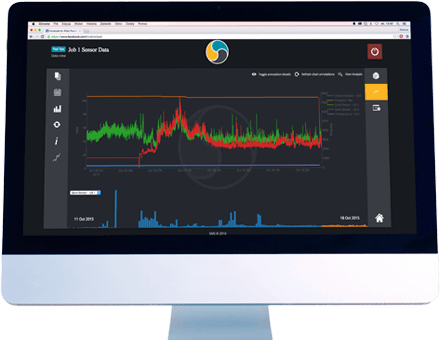

SMS successfully completed sand injection calibration of eight (8) acoustic sand detectors through 19 separate sand injections in total (minimum of 2 per location). The acoustic sand detectors picked up the acoustic signals from the injected sand passing the detectors. This data was captured in the software and graphed against solid free production signals. Matched against known flowrate velocities acquired during the injections. The calibrated data was then used to output reliable “sand rate” values from the detectors. Detectors now provide an accurate quantifiable sand rate (gr/s) value. SMS successfully completed maintenance of all 8 x acoustic sand monitors, including completion of sensitivity tests to confirm reading validity. |

Value to Client:

|

To download this case study please click here

| Contact us at This email address is being protected from spambots. You need JavaScript enabled to view it. or click here for more details on our services. |